![]() Some of the comments here assume that you are your skate sharpener is expert enough to reshape your blade profile - especially what I call the sweet spot (by my definition) of your blade. And perhaps to grind trim off the tip of the drag pick if it is too long. That isn't a big deal, but many, perhaps most sharpeners aren't at all that competent. You are often lucky to find

a sharpener who

doesn't accidentally change the shape of your blade, or takes off so much metal

every time that you need a new blade every few sharpenings. The only option for some

people is to get a blade whose initial shape and size works for them. Unfortunately,

for many people, that means buying several expensive blades until something works

right. If you've a good coach, they may be able to give you a good guess, but their

own foot shape is probably different from yours, so that doesn't always work.

Some of the comments here assume that you are your skate sharpener is expert enough to reshape your blade profile - especially what I call the sweet spot (by my definition) of your blade. And perhaps to grind trim off the tip of the drag pick if it is too long. That isn't a big deal, but many, perhaps most sharpeners aren't at all that competent. You are often lucky to find

a sharpener who

doesn't accidentally change the shape of your blade, or takes off so much metal

every time that you need a new blade every few sharpenings. The only option for some

people is to get a blade whose initial shape and size works for them. Unfortunately,

for many people, that means buying several expensive blades until something works

right. If you've a good coach, they may be able to give you a good guess, but their

own foot shape is probably different from yours, so that doesn't always work.

Fitters are told to select the blade length (see here for previous discussion on blade length) and mount position by the boot outsole length and position, but there is usually no reason why that should happen to be best for you, and makes no sense whatsoever.

As far as blade shape and length, where the blade sweet spot (the point where the long-wise "rocker" curvature changes - but be warned that not everyone uses my definition of sweet spot, as mentioned at the earlier link) is relative to the ball of your foot matters, and how easy it is to reach your toe pick. If the sweet spot is just a little bit forwards of the ball of your foot (where it bends), which makes it easy for you to control motions back and forth across the sweet spot, and the toe pick feels like it is where you want it to be, then the blade is right for you. But you have to be able to feel where your sweet spot is to take full advantage of it - so if the other things check out, ask your sharpener to work on that. The blade length therefore the position of the back of the blade matters if you lose balance, or if you tend to accidentally cross step one blade on the other.

Note that some blades (most JW blades) have 3 rocker length segments, and therefore 2 sweet spots. But the forward rocker length segment is simply the "non-skating zone" that cannot be skated on (except maybe when you push down very hard, in jump takeoffs and landings, or on very warm, soft ice), so the forward sweet spot is largely irrelevant. However, it is the point on a new blade where the toe pick starts to touch the ice, and is therefore used in scratch spins, 3-turns, etc. After a few sharpenings, it becomes inaccessible, unless you trim the drag pick.

Two great pages on blade shape that among other things explains the relationship between the sweet spot and your foot shape are

Scarlet Skater: Choosing Figure BladesA good sharpener can emphasize the sweet spot (make it a sharper transition or make it change directions a little), to make it easier for you to find. He/she can also move the entire blade forward and back to play with the toe pick position.

I herein summarize other sections pertaining to balance.

1. As mentioned on a prior page, if your foot isn't as tight as you can stand, without hurting or squishing your toes together, the boot may be too loose, by size or by lacing, so you tend to lose control of what the boot is doing - in which case you need to tie the laces tighter, or add stuff inside to take up space. It may also be too tight or loose in specific points; that too was discussed on a prior page.

2. I would look first at whether it is equally easy to reach an inside or outside edge before you have put much weight on the foot. (Test all 8 edge combinations of inside and outside, left and right, forward and back: LFI vs LFO, RFI vs RFI, LBI vs LBO, RBI vs RBO.) In particular, I want the relative height of the left and right sides of the insole to be such that when I put my foot on the ice, it naturally places the edge in the middle, between the inside and outside edges, and I want to have equal pressure on the left and right sides of the bottom of my foot.

We have already discussed taping and other methods to equalize pressure on prior pages.

E.g., if your foot is easier to put down initially on an inside edge than an outside edge, stick tape underneath one side of the insole. I think that for most people, you would stick the tape on the bottom of the insole underneath the inside edge of your foot. (For reasons I don't fully understand, a few people find it works better to stick the tape on the opposite side, so try that too.)

(Also, if it is easier to put down initially on an outside edge than an inside edge, reverse "inside" and "outside" in the above discussion.

The front and back of your foot are different, so you can use a different taping front and back to reach both forward and outside edges symmetrically.

Note that shimming - i.e., placing tape between the outsole of the boot, and one side of the blade mounting plates, has almost the same effect - but may be better if there isn't enough space inside the boot for tape under the insole, and your foot feels too tight.

3. Is it equally easy to hold inside and outside edges in 1-foot glides once the initial edge has been placed?

Many people have one or both feet collapse asymmetrically as they put weight on them. If it is substantially easier to hold inside edges than outside edges while gliding on one foot, your blade may be mounted "wrong", for moves beyond the first several lessons, as many (perhaps most) beginner blades are. What you probably want to have happen is for the foot to naturally hold the edge that you initially put it down on. Offsetting the mount to the inside may make your weight tend to shift to the outside, as you put weight on it, which is what you want.

The front and back of your foot are different, so you can use a different sideways offset front and back, so you can hold forward and backward edges.

4. If your boots and blades are set up to make you naturally symmetric, and it is still hard to hold your outside edges, then body posture, muscle strengthening, and lots of practice, are all you can do.

You should feel comfortable skating balanced over one foot. Check your balance while skating on one foot glides. (But some coaches prefer to balance on two feet, because they spend most of their time that way.) Make sure you do not need to use muscles on one side more than the other of your foot and leg to maintain balance, and that both sides of the bottom of your feet press with equal pressure on the bottom of your boot.

The position and orientation blades are mounted in affects your balance and foot pains quite a bit. As mentioned earlier, I prefer to modify balance by changing the shape of the insole, so the blade can rest under the part of the foot and body best designed to bear its weight. Most boot fitters offset the blade mount to one side to achieve this. If taken too far, offsets makes your foot very sore, and results in unequal loads on the sides of your bone (creating possible bending and fracture) and can create overuse injuries of your muscles and ligaments. Offsets can also twist the boot out of the shape intended by the boot maker. At least one prio boot maker, Klingbeil, voided warranties if the boot had such twisting. But offsets work quite well if they do not have to be offset more than a very small fraction of an inch (a small fraction of a cm).

Incorrect skating technique can also create imbalance, and generally will for beginners, who usually place all their weight on the inside edge - ask your coach if this is the problem. This is because most beginners are afraid to put weight on the outside of their blades, for fear of falling over. Asymmetric or uneven blade edge sharpening can create the same effect, so look at the edges carefully.

If the mounting plates are mounted to the boot sole in such a way there is any space between it and the boot sole anywhere, the plates and the blade will warp and twist, which makes it hard to skate. A very few blades and boots are "co-planar" which means the parts of the sole where the plates mount, and the mounting plates themselves are in one plane, making it easy to move around to your preferences, but some (I think Klingbeils) are not. You can use a belt sander to make a boot co-planar - but not on composite construction boots like Edea, because the outsoles are usually too thin, so you can't sand anything away. But some blades have the front and rear mounting plates in different planes, in which case you would not want the boot bottom to be co-planar. Another technique to fill the spaces is to use "shims" - e.g., thin pieces of leather or athletic tape or something cut from a hockey puck, etc. - between the boot and blade so they do match. If you need a thick shim, sand it into a wedge shape, so it will press equally on different parts of the area of contact.

The blades should also be vertically aligned when you are balanced over one foot, so you don't tend to skid. Shims, or appropriate sanding of the bottom of the outsole, can fix this problem too.

Most people's bones, muscles and ligaments are organized for weight support

to go through a line from about the middle of the heel, to the midpoint between the

big and second toes. That is the line along which blades should usually be mounted.

The mounting plates should usually be mounted to be centered forward and back in

relationship to the foot.

Most people's bones, muscles and ligaments are organized for weight support

to go through a line from about the middle of the heel, to the midpoint between the

big and second toes. That is the line along which blades should usually be mounted.

The mounting plates should usually be mounted to be centered forward and back in

relationship to the foot.

Generally speaking if that does not create balance, it is because of unequal pressure on the two sides of the insole, or on the sides of the boot - discussed earlier. But the exact placement that makes your feet most comfortable and least sore may vary.

Do a "test mount" using the sliding hole slots in the blade mounting plates to make sure you have the position and orientation right. You have to skate gently, avoiding jumps and only doing gentle step turns.

Once you have the mounting position right, you can do a final mount by adding an extra screw to the front and back section of the mounting - two if you do high jumps - using the round holes. Leave the slotted hole screws in place to help hold the plate on.

Follow Bill Schneider's recommendations on screw types, sources and sizes. He buys screws from McMaster-Carr in the US. Bill says poorer quality screws often rust or break. Bill and others say round head screws, whose heads have flat bottoms, grip the slotted (test mount) holes better. Flat head screws, whose heads have conically shaped bottoms, fit the round (permanent mount) holes in most blade mounts better - but I suggest you look at the mounting plate holes to be sure. (My note: round top head screws don't always have flat bottoms to the heads, nor do flat top screws always have conical bottoms to the heads - and it is the head bottom shape that matters.) He buys #6 size, 18-8 thread stainless steel screws with "sheet metal" (i.e., self-tapping, not "machine screw") threads. For slotted holes use round (or pan) head screws: #6 x 1/2" (part #92470A148)in front, #6 x 3/4 inch" (part #92470A151) on heel. For round holes use flat head screws: #6 x 1/2" (part #90065A148) in front, #6 x 3/4" (part #90065A151) on heel. If you strip a screw hole, use #8 screws instead of #6. Larger, but they still fit the mounting holes.

Self-tapping screws always work better and are less likely to split and damage the material (in this case, the sole) if you first drill a smaller diameter "pilot hole" and use it to guide the screw when you screw it in the first time. When screwing a self-tapping screw in or out, always press down on the screwdriver with about 5 pounds or so of weight, to avoid stripping the hole or the head of the screw - especially with soft materials like leather, or with those awful Phillips head screws.

Bill prefers Phillips head screws because they are easier to use with powered screwdrivers. I prefer [i]anything[/i] else, hex head and possibly square head screws best, because Phillips heads strip (become too damaged to remove with a screwdriver) very easily, and then have to be removed with screw remover/extractor tools (there are ones that fit reversible power drills too - Alden GrabIt is a good brand). Another approach is to use a tap and die set to create a new reverse direction screw thread inside the original screw, and then screw a reverse threaded screw in to force it out. Both these things have the potential to damage your delicate leather sole, so be careful. (I think Phillips head screws are universal symbol of shoddy construction.) Heads with small indented hexangonal hole centers, that you need hex keys to turn, are easily stripped too, because the hexagonal holes are so small.

If after doing a "permanent" mount, you decide to change the mount position, or you change blades, you need to fill in the old holes for two reasons:

If the hole is only stripped and doesn't hold the screw in well, you can avoid filling in the hole by just using a slightly higher diameter screw, as per Bill's recommendations.

Filling the hole can be done two ways.

Someone who is skilled with power drills could do something much more elaborate, which lets you easily and quickly change blades. Drill the holes all the way through, and use a nut inside the boot, under the insole, to screw a bolt into. Drill a shallow inset in the bottom of the boot, so the nut wouldn't push into the foot. Show skaters sometimes do this because they often skate on "artificial ice" (lubricated plastic), which wears down edges quickly, so they may change blades every hour or two, between sharpenings. Obviously a fully drilled hole would be a lot harder to undo and relocate. Interestingly, it is the mounting method many roller skates use.

Be sure to periodically retighten your screws. If they come loose, your holes will strip.

Caution: An old style (Jackson) Ultima Matrix mount system, sometimes called Matrix I, had relatively inexpensive removable blade runners - a great idea implemented somewhat badly. (Don't confuse it with the newer Ultima Matrix system which does not have removable runners, though the Matrix RXS system has removeable runners too - but not at the toepick, and which is not cheap.) It had very soft aluminum bolts and nuts, and very small hex key heads. They keep coming loose, and need to be tightened often, and the hex keys would wear a little larger and rounder every time you tighten them or replace blade runners.

This is a problem partly because many people like me who still have these mounts find they need to remove the "runners" from the blade chassis to get some skate techs sharpen them, because the old Matrix system gets in the way of some sharpening machines, unless they use special blade holders. (Paramount blades have a similar problem with some blade holders - but their runners are NOT removeable.) Though I eventually started sharpening my own blades with the Pro-Filer system hand tool, that had no problems on my Matrix I blades. That said, the current Matrix blades might be harder to sharpen with Pro-Filer toos.

It helps to buy several hex key sets, whose hex keys invariably have almost infinitesimally different sizes, and to buy both metric and ASE (English measure) sizes, and to use the key that fits the current hole size as closely as possible. That way they wear more slowly. It also helps to buy a spare set of bolts, just in case the hole became too rounded to be practical. The soft aluminum threads also strip easily, so put the nuts on carefully.

The problem is so severe that I considered grinding down stainless steel bolts and nuts to fit, but never got around to it.

In addition, the blades would "click" and move around every time you touched the ice, because there was a little space between the top of the runner and the surface it should have touched, and Ultima hadn't taken thermal expansion and contraction into account - many people found it helped to add in a little foam pad in between. Unfortunately, Ultima dealt with the problems by stopping the manufacture of this otherwise very cost effective system, and stopped selling the blade runners, leaving a lot of us in the lurch.

Hockey boots have had several different removable blade runner systems, at least one per manufacturer, that required special purpose tools. Recently, at least two hockey companies have provided very quick runner interchange systems that allow you to remove and insert a blade by squeezing a trigger-like device. I tried that, and it required a lot of force to squeeze - I might need a vice or clamp to do it.

Ultima's basic idea, with sideways mounted bolt and nut that go on either side of the blade, was simpler and better, if they had used the right materials for the bolts and nuts, and hadn't used those thin hexagonal holes in the heads of the bolts and nuts. It is a shame no one else has stepped in to make new runners that fit the Ultima Matrix system, or to make stainless steel or titanium bolts and nuts that fit, or to make a better engineered removable figure skating blade system altogether. Not only would such a system be more cost effective than replacing the blade and mounting plates, but it makes it easy to change blades for remote or delayed sharpening. People also often used to put their skates in carry-on luggage, but placed two pair of blade runners in different pieces checked luggage, to comply with some airport security people who are afraid blades are dangerous, while making it likely that at least one pair would arrive without getting lost.

It is very important that figure skate sharpening be done by someone who knows how to sharpen figure skating blades. Ask your coach and ask good skaters around the local rinks to find the best sharpener in the area.

Hockey blades are sharpened quite differently. A single poorly done sharpening can ruin a expensive blade. For example, a hockey sharpener who doesn't understand figure skate blades may shave off the toe pick, or round off the back of the blade. Speed skating blades are also sharpened differently.

Poor sharpeners may also use a "hollow radius" - a measure of the concave curvature across the smallest blade dimension, between the inside and outside edges, that is different from what you are used to. If it is too large, your blade will act as though it is not very sharp, and you will skid easily. If it is too small, it may act sharper, and bite into the ice more than you are used to, and the sharpening will also wear down and need to be redone more often, because the included angle is narrower and more fragile. Further, each time the hollow radius is altered, the sharpener wastes a lot of metal, and therefore greatly shortens the lifetime of the blade. Each sharpening wheel is shaped a little different after the skate tech dresses it, so going to multiple sharpeners will again waste a lot of metal. (How often sharpening wheels are dressed depends on the skate tech - a few actually re-dress between the skates of a pair). But time is money, so many skate techs sharpen several blades without dressing in between.) A good consistent sharpener only needs to remove 2 or 3 thousandths of an inch to keep the edge keen, though they must remove more if you wait long enough to let the bottom go flat. (Letting the bottom go somewhat flat isn't bad in itself, if you don't need and like sharp edges. It is a matter of taste.)

Poor sharpeners may also alter the "rocker radius" - a measure of the convex curvature along the long dimension of the blade. A good sharpener can "fix" the rocker profile and restore it to what it was, but doing so wastes a tremendous amount of metal. (Blades with 8' rocker radius - less curvature - are supposed to go faster than 7' rocker blades, though the fastest figure skating blade I've used - the MK Dance - has 7' rocker radius, because it is thinner. 8' rockers are also supposed to have better stability for jump landings. Blades with shorter rocker radius - more curvature - turn, spin and twizzle better.

Poor sharpeners may also fail to understand that good figure skating blades are designed with more than one rocker radius. This is partly to create a "sweet spot", approximately below the ball of your foot, where turning and spinning are easier because it has a curvature discontinuity (like a top) or a region of reduced rocker radius. You will spin like a top if the blade is shaped like a top, with a sudden convex change of rocker where you want to spin, or with a lower radius rocker ("spin rocker") where you want to spin. The rocker change is also partly to create a region next to the toe pick which is not skated on, in order to make the transition to the toe pick stronger. See, for example, these blade shapes, and these toe pick shapes.

Note that most turns and some spins also involve dragging the toepick (specifically the drag pick) on the ice, so there are two points of contact. So the sweet spot on a two rocker blade is not spun on for those spins.

Please recognize that blade shapes are controversial, and not everyone agrees on the best way to shape or sharpen a blade. It must work with your individual body. If a bad sharpener creates a uniform rocker radius, with no sweet spot - extremely common - it will be harder to turn and spin. A very good sharpener can restore the original shape, or give you a custom rocker profile.

If you sharpen your own blade, or even if you don't, it is a good idea to photocopy (or at least trace the edge of) the blades (be careful not to scratch the glass) when they are as new as possible. This lets you restore the original rocker profile, if desired. It is very easy to accidentally alter the profile over time by many sharpenings. Some sharpeners insist on modifying the original profile before selling you the blade - but I encourage you to photocopy them first, in case the sharpener eliminates the sweet spot, or makes you unhappy. If you like what they did, photocopy that.

A poor sharpener can also make one edge longer than another - making it hard to stay balanced - or make the edge heights non-uniform, making skating quite difficult.

If you walk off-ice with your blades, even if it is on the rubber mats often used just outside the skating area, it can completely destroy the sharpness of the edge, in a step or two, especially if you use very sharp edges. Use blade guards, which you remove as you step onto the ice. But, if you step onto the ice while wearing the guards, and don't realize it, you will probably fall, so be careful. An alternative adequate for rubber mats, but not for harder surfaces, is to walk on your toe picks, but that requires some balance, and it does gradually reduce the sharpness of your toepicks. I often use hard plastic blade guards to walk on, but switch to breathable terrycloth guards afterwards to prevent rust (see next page), and take even those off when they aren't needed to protect the edges.

If you can find out your ROH, you could start by buying a Figure Pro-Filer kit. It's not fast enough for major blade shape modifications, but it is a good tool, for under $100, that imposes a constant ROH. Unfortunately they are no longer made.

However, the gap widths on Pro-Filers vary. You may need to file it if your blade won't fit, or add tape on each side of the gap if it is loose. (In fact, thin tape is a good idea, so it doesn't scratch the blade.

If that is too expensive, I also like the old Berghman skate sharpeners, which I think stopped being made around 1950 or 1960, but are still available on Ebay cheap. The cylindrical sharpening stones these tools use are a bit coarse and crumbly, and they only come in 1/2 inch ROH. Be sure to tape the insides of the part that grips the blade, so it doesn't scratch the blade either.

Wet the blade and the cylindrical diamond-dust abrasive (coarse) stone in the sharpener with water, not oil, because oil sometimes gets messy in your bag. Sharpen until you feel a very slight burr on each side of the blade, reversing the orientation of the sharpener every few strokes. Then use a wet flat stone (like you can buy at a dollar store, but I much prefer to use a finer grain flat stone - about 5000 grit) to hone (polish and push the burr from horizontal to vertical) - that burr, which you can think of as a flattened, stretched, knocked down tip of the edge, becomes the final tip of your edge. (The edge on almost any steel cutting tool, such as knives, works the same way.)

Total time is usually at most a few minutes / blade, unless you have let the edge get very dull. Try to remove as little metal as you can each sharpening. If you can measure that with a calipers or micrometer (use very little pressure, so as not to damage the edge), .003 inches or less is what about right when using powered sharpening machines, but you can remove a good less with a hand tool, because at hand sharpening speeds, you reshape the metal as much as remove it. That extends the effective lifetime of the blade to more sharpenings.

Sharpen roughly every 40 hours of use. Some people sharpen more often, but do a very slight quick sharpening each time - if they love very, very sharp blades.

I only use the coarse grain (diamond-dust) Pro-Filer stone. The fine grain stone is nice after you have used the coarse stone if you want extremely sharp edges.

The biggest things to pay attention to are:

I have often argued that the most common rocker radii measuring tool has measurement errors, because it only looks at 3 very small points, and because it doesn't measure down the blade center or along the edges, but is offset in such a way as to be sensitive to nicks and scratches along the sides. (E.g., it may not measure the same radii along both sides.)

I believe you can get a better measurement by visual comparison.

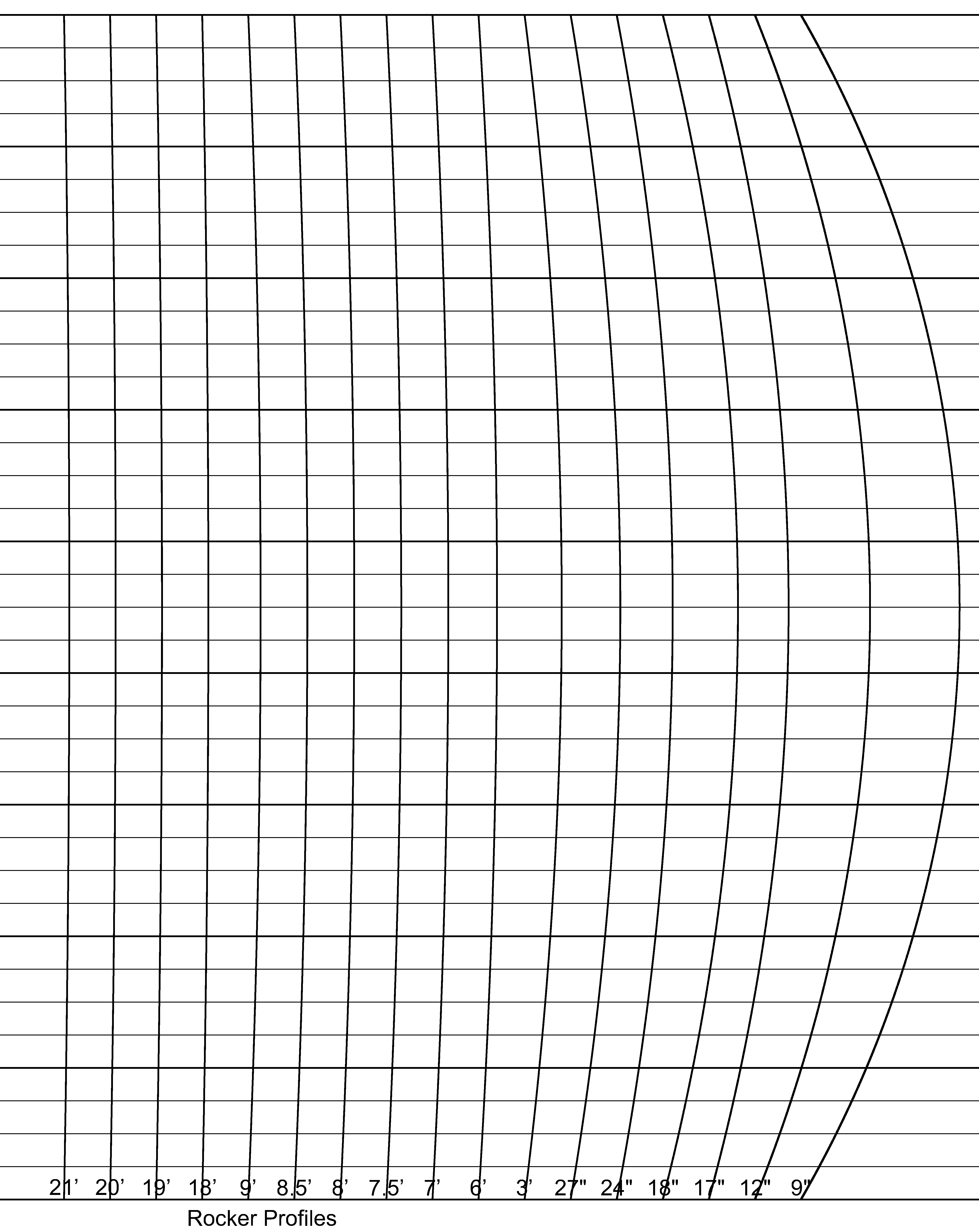

If you want to measure your blade rocker, download and print this image of rocker curve templates:

For properly scaled curves, or if that doesn't show on your browser, look here.

If your printer scales it right, the horizontal grid lines will be .25" apart, and the curves will be .35" apart on the x-axis. Otherwise, enlarge or shrink the printed page by the appropriate factor to make it so. Cut the templates out, leaving a little white space around the boundaries, then place one behind your blades, so that you can just barely see how the blades compare to the black lines on the paper. There is not much visible difference between 7', 7.5' and 8' rockers - which is why some of us aren't sure it matters much. On the other hand, spin rocker radii (the part forwards of the sweet spot) curves are a lot different, and many of us think that matters a lot.

Here are some more rocker curves, with lines along radii instead of all vertical, and with inch scales on the sides. I prefer these, because when a point along the blade is in contact with the ice, it is approximately horizontal, and the radii are vertical there. Here they are:

They were created using my DrawArcs program.

I also have a DrawBlade program to draw figure skating blade runners, as part of an investigation into the idea of making our own blades.